Mills, Inoteck

Description

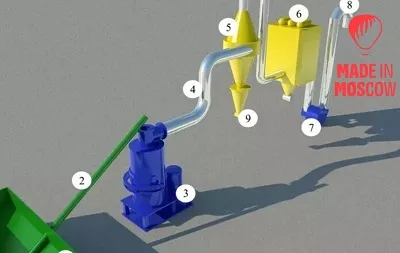

The operating principle of the mill is the grinding of the incoming raw material in vortex flows against the armor plate, in the absence of grinding bodies. The grinding bodies are particles of the processed material itself. All complexes are a complete technological line, controlled by one operator and can be easily integrated into any other technological lines, as agreed with the Customer. It is possible to install the equipment on a movable automobile platform. An important feature of the mills is the possibility of simultaneous drying and grinding, the humidity of raw materials can reach up to 50-60%. Applications of Mills Ore processing - grinding of ore and non-metallic materials: rocks and ore concentrates, including wollastonite, asbestos and mica. Processing of industrial waste from mining and metallurgical and heat and power processing: slags and dumps of thermal power plants, tailings of mining and processing plants, pyrite cinders, etc. Fuel production: coal grinding for water-coal fuel. Production of superhard materials: for supergrinding of metal, ceramic and abrasive powders to produce functional and structural ceramics, metal ceramics, cutting tools, refractories and heat insulators. Production of metal powders: for powder metallurgy and other needs by mechanical grinding of chips and sheet metal. Production of mineral pigments: grinding of graphite, coke, soot and antifriction materials. Manufacture of building materials: fillers for paint and varnish materials. Production of agricultural products: for obtaining mineral fertilizers, plant protection products and mixed fodder. Processing of waste from various industries: co-milling-mixing of components. The main disadvantage of all mills on the market, where material is ground at high speeds, is the low wear resistance. Therefore, the replacement of consumable (fast wearing) parts is expensive or requires frequent replacement (every other day). Foreign manufacturers require additional lifting equipment for almost complete disassembly of the machine. In our variant, we offer very simple technical solutions and not expensive replacement parts: the vortex converter is protected by cladding plates and can be changed in minutes. The armor of the mills is also protected by hard-fused plates and can be easily changed by one person in one hour. Foreign complexes of well-known companies cost at least 25 million rubles, and low quality from China from 10 million rubles. Our complex costs from 5.8 million rubles, and its maintenance costs are reduced tenfold.