AXELOT WMS X5

Description

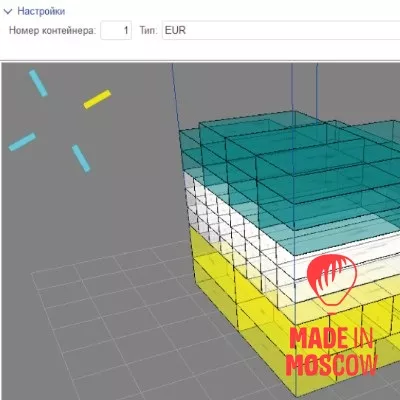

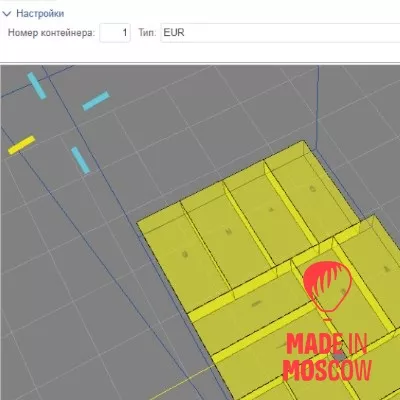

AXELOT WMS X5 is the fifth generation of the warehouse management system developed by AXELOT. • Regulatory and reference information management • Warehouse topology management • Warehouse accounting in different sections • Planning of shipments and receipts • Incoming flow management • Outbound flow management • Warehouse Process Management • Resource and personnel management • Management of warehouse equipment and machinery • Cost accounting and allocation • Billing of warehouse services • Analyzing key warehouse performance indicators AXELOT WMS X5 is a component of the comprehensive AXELOT SCM supply chain management platform and seamlessly interacts with other components of the platform in real time. AXELOT WMS X5 can be implemented separately or together with other components of the AXELOT SCM platform. Who is the product intended for? AXELOT WMS X5 software product can be used both by manufacturing and trading companies to manage their own warehouse logistics, and by specialized 3PL-operators within the framework of providing storage and warehouse processing services, as well as complex logistics services to third-party customers. AXELOT WMS X5 Features: • Developed as a component of the AXELOT SCM comprehensive supply chain management platform • Extensive functionality • High level of parameterization • High performance • Visualization of settings • Unified and intuitive user interfaces • Proactive diagnostics of system and warehouse conditions • Mobile client on AXELOT mobile platform • Event-based model of interaction with other AXELOT SCM and ERP components • Support for multi-lingual user interfaces In AXELOT WMS X5 warehouse topology is created using a specialized visual editor. Unlike the traditional way of forming the warehouse topology (when the topology is formed through the creation of a cell record in the cell directory), the visual formation of the warehouse topology in AXELOT WMS X5 allows you to: • get a complete visualization of which zones and cells have been created and how correctly; • use the geographical position of zones and cells relative to each other in planning algorithms, which provides more accurate planning of warehouse operations, minimizes mileage and increases the productivity of operations; • generate operational and analytical reporting with visualization of information on the warehouse plan.