OPGW-Optical Fiber Ground Wire

Description

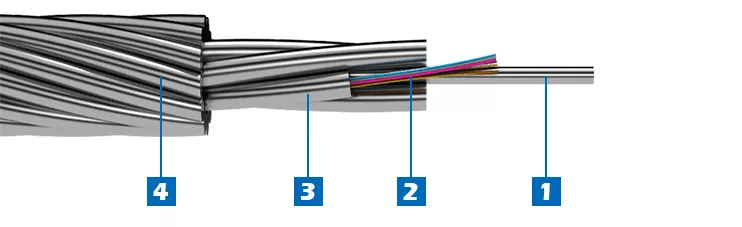

Application: Optical Ground Wire Layer Stranded combines excellent mechanical and electrical properties with much higher zero fiber strain margin to enhance long-term optical reliability. It is also more flexible and crush-resistant than other design types which makes pulling it in faster and makes it possible to pull farther and through more angles. Constructions: The conductor is consist of aluminum-clad steel wires / 6201-T81 aluminum alloy wires concentrically stranded. The stainless steel tubes with fibers will be laid in the layers according to specific requirement on fiber count, strength and electrical properties. 1. Central strength member (aluminum-clad steel or aluminum alloy wire) 2. Optical fiber 3. Stainless steel tube filled with water-blocking gel 4. Stranded wires (aluminum-clad steel wires and/or aluminum alloy wires) Features * Up to 432 fibers * Layer stranded construction provides more flexibility and options on design. * ACS wires are highly corrosion-resistant * Optical ground wire (OPGW) shields high voltage conductors from lightning strikes * Aluminum alloy wires provide conductivity for fault current Standards: ITU-TG.652 Characteristics of a single mode optical fiber. ITU-TG.655 Characteristics of a non-zero dispersion -shifted single mode fibers optical. EIA/TIA598 B Col code of fiber optic cables. IEC 60794-4-10 Aerial optical cables along electrical power lines-family specification for OPGW. IEC 60794-1-2 Optical fiber cables -part test procedures. IEEE1138-2009 IEEE Standard for testing and performance for optical ground wire for use on electric utility power lines. IEC 61232 Aluminum -Clad steel wire for electrical purposes. IEC 60104 Aluminum magnesium silicon alloy wire for overhead line conductors. IEC 6108 Round wire concentric lay overhead electrical stranded conductors. Packing: Non-returnable wood drums, wood drums steel frame reinforced or steel drums as per request Length Tolerance per drum ± 2%