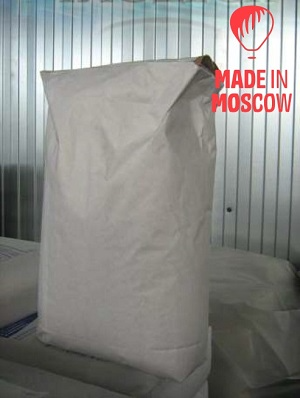

Exterior birch plywood Grade 3/4 21 mm 1.5x3

As is known, GOSTs regulating the quality of plywood stipulate two classes of water resistance - water-resistant plywood (plywood FC) and plywood of increased water resistance (plywood FSF). FSF plywood is made of birch, beech or pine veneer with the use of phenol-formaldehyde adhesive resins. The l...

As is known, GOSTs regulating the quality of plywood stipulate two classes of water resistance - water-resistant plywood (plywood FC) and plywood of increased water resistance (plywood FSF). FSF plywood is made of birch, beech or pine veneer with the use of phenol-formaldehyde adhesive resins. The latter cause high qualities of the material - water resistance, mechanical strength and wear resistance. Such properties allow FSF to be used in construction (roofing and concrete works), car building, as well as in automobile production. Nowadays, FSF plywood is one of the most widespread "non-wood" lumber widely used in construction, carriage industry and packaging production. The reason for such popularity lies in its numerous and undoubted advantages, which will be discussed in this article. However, a little theory to start with. Production FSF is obtained by gluing several layers of husked veneer with phenol-formaldehyde resins. For this purpose, as a rule, birch or coniferous veneer of small thickness is used. The choice of these species is conditioned by their wide distribution in our forests: in Europe, New Zealand and some other countries oak, maple, hornbeam and even pear are widely used for production of plywood of different grades. The veneer is glued together under pressure at elevated temperatures. The resulting sheets are cooled, labeled and, after a short curing period, assembled in packages of 10 or 20 pieces. FSF is characterized by high tensile and bending strength, and these characteristics are practically unchanged in case of temperature and humidity fluctuations. In addition, the sheet of this grade has increased moisture resistance, so it can be widely used in outdoor work. As for the ease of processing, the plywood is perfectly sawed, drilled and fastened with nails and screws. All this together allows it to be used in a wide variety of construction and production spheres. Area of application For roofing For floor Exterior work Formwork Packing Other